Optimised processes and a happy dispatcher

The situation

A mid-sized industrial park operator needs to create the correct conditions in terms of the operating environment and infrastructure if it wants to reliably supply the companies at its site with energy at competitive prices and in accordance with high environmental and safety standards. Each day it was necessary to make decisions in regard to whether the required energy would come from the operator’s own systems or whether it would be procured on the wholesale energy markets.

The challenge

In the context of a feasibility study, the industrial park operator was looking to automate the process flows with which it makes energy available, with all of this ultimately intended to be integrated into the processes of the existing power plants. A situation like this is exactly where Seven2one can help the most.

The solution

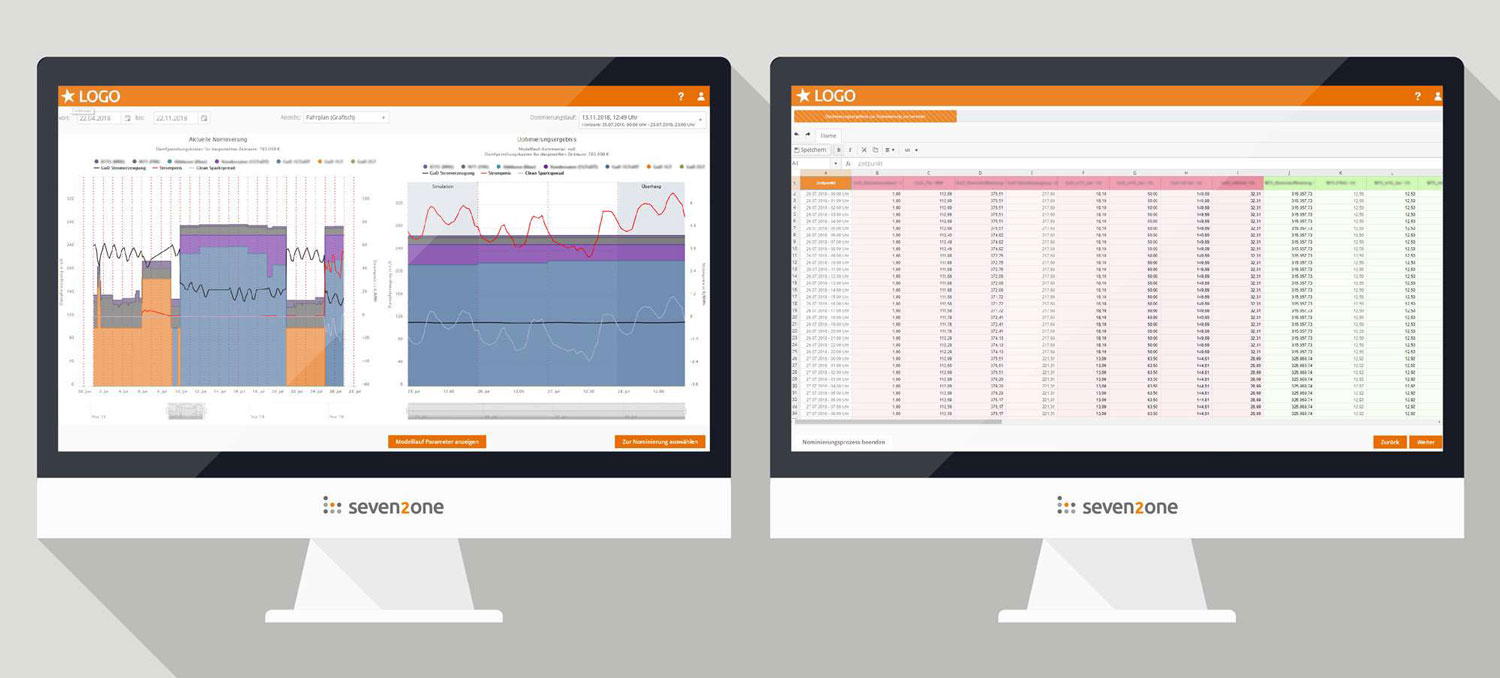

To automate the client’s process flows, we provided the client with a platform that functions as a data hub. The hub uses a variety of interfaces to automatically collect data regarding forecasts, markets, weather and power plant availability in a wide array of formats. This means that the dispatcher who is responsible for power plant control no longer has to manually collect information from Excel spreadsheet or other file formats or manually make it available to the optimisation model.

The optimisation process can also be triggered from the Seven2one platform – an option that is always useful when the data changes, for example.

The optimisation allows the dispatcher to create a schedule for the plant park and adjust it at a later point in time. Schedules are stored and distributed in a variety of different ways. Using a single user-friendly interface, the dispatcher controls all steps, from preparation of the data to sending of the schedule.

The software also checks and updates the processes and their implementation. This makes it possible to map and document everything at all times in an audit-proof manner – making life easier for both the dispatcher and industrial park operator.

Project results

Automated optimisation process and the resulting editable nomination

Audit-proof record-keeping: all data and processes are documented

Low manual effort

Changes to the parameters can be taken into account more quickly.

More efficiency in the planning process